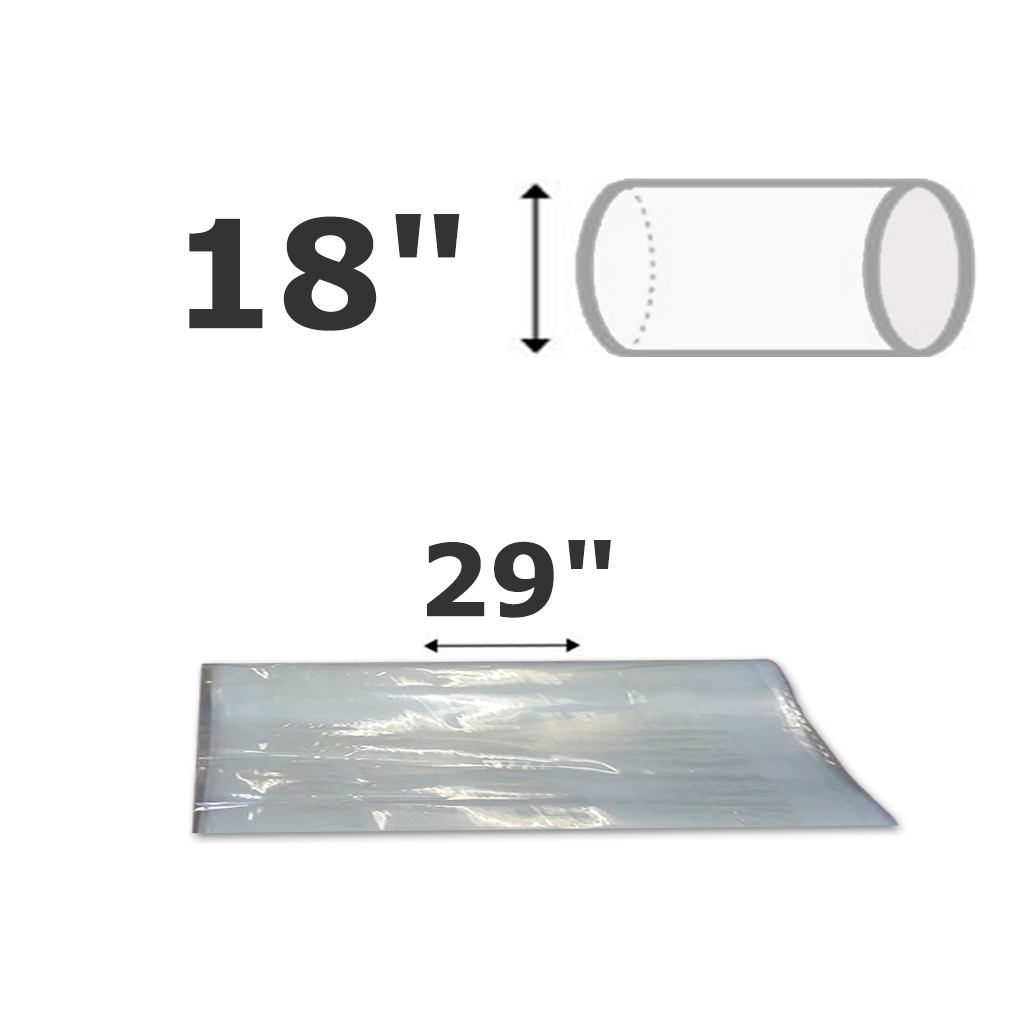

Polyethylene tubing 18" Ø (29" flat) 12 UV. 4mil (ventilation & heating)

Availability:

backordered

Shipping time if backordered::

jusqu'à 2 semaines

In case of backorder::

Only replenished IF YOU ORDER IT

Polyethylene tube also called balloon, heating tube or ventilation tube. The plastic contains a UV stabilizer. (UV treated 12 months) and its thickness is 100 microns (4mil). Tubes used in the greenhouses especially for heating to distribution by hot air or ventilation with a positive pressure ventilator (Fan jets).

| Diameter of the inflated tube | Ø 18" |

| Flat tube width | 29'' |

| Material | Polyethylene |

| UV treatment | 12 month |

| Thickness | 4 mil |

| Length of a full roll | About 1000' long (can be cut on request) |

These plastics can be tailored cut and perforated as needed. The design of the holes can be calculated precisely by having the exact specifications of fans and the environment. However you will find here a rule of thumb the number of holes and arrangement thereof:

|

Specification rules for the holes percing |

||

|

|

Warm air heating |

Ventilation to positive pressure (Fan jet) |

|

Distance between holes |

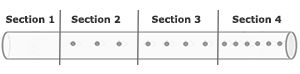

For heating, the pairs of holes are usually divided into 4 sections 1: |

For ventilation, the pairs of holes are generally evenly distributed over the length of the tube.

|

|

Orientation of holes (Projection angle) 2 |

In generally or if placed under a table: 9 and 3 (180°).

If in center of a double row, depending on the layout of the plants in the greenhouse: 9 and 3 (180°) or 8 and 4 (120°)

If the tube is at the top of the greenhouse 3 it may be preferable to make holes at: 8 and 4 (120°)

|

In general 8 and 4 (120°)

If installed at the top of a greenhouse or if placed under a table: 9 and 3 (180°)

|

|

Diameter holes |

The most used are the holes 1 3/4" in diameter 4. In doubt, used of smaller holes, the more (air is pushed less far). In general the jet scope varie from 20 to 40 times the size of the hole.

|

|

|

Number of holes |

The number of precise holes to be used varies depending on the environment, the specifications of the fan and the heating source and the conduit used to forward the air. However a general rule permits to meet most situations.

This rule permit to specifies the number of holes for a tube of 18" diameter:

Hole 1" (25 mm): 204 pairs (total of 408 holes) Section 1: no holes Section 2: 34 pairs Section 3: 68 pairs Section 4: 102 pairs

Hole 1 7/8" (47 mm): 58 pairs (total 116 holes) Section 1: no holes Section 2: 10 pairs Section 3: 19 pairs Section 4: 29 pairs

Hole 2 1/4" (57 mm): 40 pairs (total 80 holes) Section 1: no holes Section 2: 7 pairs Section 3: 13 pairs Section 4: 20 pairs This rule is conservative and may require more holes depending on your turbine. When in doubt it is always better to do fewer holes and add once tubes installed. It is easier to add holes if the number of holes is insufficient. Too many holes can cause problems 5.

Your machine performs the holes on the tube to flat, thus creating holes in pairs (both film thicknesses to flat are pierced during the operation).

|

|

|

Balancing the tubes |

When the tubes are installed it is desirable to proceed out a balancing of the tubes; a few methods can be used according to control equipment you own. However, a simple method is explained in the document accessible by hyperlink to the bottom of this page. Once the system is balanced you can record your values for replacement tubes. If no any physical changes to your installation occurs, it will be easier to order replacement the tubes subsequent years.

|

|

|

Implementation information |

Please note that the information provided are for reference only. For greater certainty of design you should contact a professional engineer.

Groupe Horticole Ledoux can not be held responsible for the result or its inconsistency.

Diameter of the holes and position are approximate and may vary.

|

|

1 A heating tube is pierced differently 4 sections:

Since air is much warmer at the exit of the heating unit, the heat of the tube and the air expelled at this stage has a high efficiency while at the end of the tube, the air is cooled and the velocity decreases, so more holes are required to maintain a uniform temperature in the greenhouse.

2 Projection angle:

The holes angle and diameter are particularly important to avoid drying up.

The air jet should not hit the polyethylene greenhouse roof or directly plants.

Contrariwise the projection angle can vary with your needs.

Projection angle suggested if along driveway: drilling only row of holes toward the driveway. If stuck on the side of greenhouse, drilling row of holes side of production. If you need a tube punched one side, you must do it yourself. Here is a technique of drilling heating holes: Mark your tube at desired places, inflate your tube and drilled with a pipe preheated (box canning or exhaust pipe on which a handle has been welded and heated with a blowtorch for example...).

3 Projection angle if the heating tube is in the top of a greenhouse:

A drilling of holes 8 and 4 (120°) is usually used in ventilation and not heating. By cons, if the tube is at the top of the greenhouse, it may be preferable to make holes at 8 and 4 (120°); which is not ideal because heat rises and because a tube under tables warms the roots of plants.

4 Diameter of the holes:

+ The holes are small, less air is projected away from the tube and there is the less the risk that the jet of air drying up the plants. smaller diameter holes make it possible to had more holes per tube and to get uniformity all along the tube. This situation applicable better when several tubes serve to heat the greenhouse.

+ The holes are big, + will the air going will away from the tube and + there is air circulation in the greenhouse but there is more risk of drying up the plants. larger diameter holes are desirable when few tubes are used by greenhouse and that air must reach distant points. However, larger diameter holes increase the drying up when the air expelled comes into contact with plants nearby.

5 Problems when many holes are drilled:

- The energy (hot air) can not get to the end of the tube;

- The tube is not rigid enough (too low static pressure) becomes limp and can block the passage of air, especially where there are obstacles.

Specifications

| Poly/Measure | Length 020' or Length 025' or Length 030' or Length 035' or Length 040' or Length 045' or Length 050' or Length 055' or Length 060' or Length 065' or Length 070' or Length 075' or Length 080' or Length 085' or Length 090' or Length 095' or Length 100' or Length 105' or Length 110' or Length 115' or Length 120' or Length 125' or Length 130' or Length 135' or Length 140' or Length 145' or Length 150' or Length 155' or Length 160' or Length 165' or Length 170' or Length 175' or Length 180' or Length 185' or Length 190' or Length 195' or Length 200' or Length 205' or Length 210' or Length 215' or Length 220' or Length 225' or Length 230' or Length 235' or Length 240' or Length 245' or Length 250' or Length 255' or Length 260' or Length 265' or Length 270' or Length 275' or Length 280' or Length 285' or Length 290' or Length 295' or Length 300' or Length 305' or Length 310' or Length 315' or Length 320' or Length 325' or Length 340' or Length 330' or Length 345' or Length 335' or Length 350' or Length 355' or Length 360' or Length 365' or Length 370' or Length 375' or Length 380' or Length 385' or Length 390' or Length 395' or Length 400' or Length 500' or Length 600' or Length 700' or Length 800' or Length 900' |

Polyethylene tube also called balloon, heating tube or ventilation tube. The plastic contains a UV stabilizer. (UV treated 12 months) and its thickness is 100 microns (4mil). Tubes used in the greenhouses especially for heating to distribution by hot air or ventilation with a positive pressure ventilator (Fan jets).

| Diameter of the inflated tube | Ø 18" |

| Flat tube width | 29'' |

| Material | Polyethylene |

| UV treatment | 12 month |

| Thickness | 4 mil |

| Length of a full roll | About 1000' long (can be cut on request) |

These plastics can be tailored cut and perforated as needed. The design of the holes can be calculated precisely by having the exact specifications of fans and the environment. However you will find here a rule of thumb the number of holes and arrangement thereof:

|

Specification rules for the holes percing |

||

|

|

Warm air heating |

Ventilation to positive pressure (Fan jet) |

|

Distance between holes |

For heating, the pairs of holes are usually divided into 4 sections 1: |

For ventilation, the pairs of holes are generally evenly distributed over the length of the tube.

|

|

Orientation of holes (Projection angle) 2 |

In generally or if placed under a table: 9 and 3 (180°).

If in center of a double row, depending on the layout of the plants in the greenhouse: 9 and 3 (180°) or 8 and 4 (120°)

If the tube is at the top of the greenhouse 3 it may be preferable to make holes at: 8 and 4 (120°)

|

In general 8 and 4 (120°)

If installed at the top of a greenhouse or if placed under a table: 9 and 3 (180°)

|

|

Diameter holes |

The most used are the holes 1 3/4" in diameter 4. In doubt, used of smaller holes, the more (air is pushed less far). In general the jet scope varie from 20 to 40 times the size of the hole.

|

|

|

Number of holes |

The number of precise holes to be used varies depending on the environment, the specifications of the fan and the heating source and the conduit used to forward the air. However a general rule permits to meet most situations.

This rule permit to specifies the number of holes for a tube of 18" diameter:

Hole 1" (25 mm): 204 pairs (total of 408 holes) Section 1: no holes Section 2: 34 pairs Section 3: 68 pairs Section 4: 102 pairs

Hole 1 7/8" (47 mm): 58 pairs (total 116 holes) Section 1: no holes Section 2: 10 pairs Section 3: 19 pairs Section 4: 29 pairs

Hole 2 1/4" (57 mm): 40 pairs (total 80 holes) Section 1: no holes Section 2: 7 pairs Section 3: 13 pairs Section 4: 20 pairs This rule is conservative and may require more holes depending on your turbine. When in doubt it is always better to do fewer holes and add once tubes installed. It is easier to add holes if the number of holes is insufficient. Too many holes can cause problems 5.

Your machine performs the holes on the tube to flat, thus creating holes in pairs (both film thicknesses to flat are pierced during the operation).

|

|

|

Balancing the tubes |

When the tubes are installed it is desirable to proceed out a balancing of the tubes; a few methods can be used according to control equipment you own. However, a simple method is explained in the document accessible by hyperlink to the bottom of this page. Once the system is balanced you can record your values for replacement tubes. If no any physical changes to your installation occurs, it will be easier to order replacement the tubes subsequent years.

|

|

|

Implementation information |

Please note that the information provided are for reference only. For greater certainty of design you should contact a professional engineer.

Groupe Horticole Ledoux can not be held responsible for the result or its inconsistency.

Diameter of the holes and position are approximate and may vary.

|

|

1 A heating tube is pierced differently 4 sections:

Since air is much warmer at the exit of the heating unit, the heat of the tube and the air expelled at this stage has a high efficiency while at the end of the tube, the air is cooled and the velocity decreases, so more holes are required to maintain a uniform temperature in the greenhouse.

2 Projection angle:

The holes angle and diameter are particularly important to avoid drying up.

The air jet should not hit the polyethylene greenhouse roof or directly plants.

Contrariwise the projection angle can vary with your needs.

Projection angle suggested if along driveway: drilling only row of holes toward the driveway. If stuck on the side of greenhouse, drilling row of holes side of production. If you need a tube punched one side, you must do it yourself. Here is a technique of drilling heating holes: Mark your tube at desired places, inflate your tube and drilled with a pipe preheated (box canning or exhaust pipe on which a handle has been welded and heated with a blowtorch for example...).

3 Projection angle if the heating tube is in the top of a greenhouse:

A drilling of holes 8 and 4 (120°) is usually used in ventilation and not heating. By cons, if the tube is at the top of the greenhouse, it may be preferable to make holes at 8 and 4 (120°); which is not ideal because heat rises and because a tube under tables warms the roots of plants.

4 Diameter of the holes:

+ The holes are small, less air is projected away from the tube and there is the less the risk that the jet of air drying up the plants. smaller diameter holes make it possible to had more holes per tube and to get uniformity all along the tube. This situation applicable better when several tubes serve to heat the greenhouse.

+ The holes are big, + will the air going will away from the tube and + there is air circulation in the greenhouse but there is more risk of drying up the plants. larger diameter holes are desirable when few tubes are used by greenhouse and that air must reach distant points. However, larger diameter holes increase the drying up when the air expelled comes into contact with plants nearby.

5 Problems when many holes are drilled:

- The energy (hot air) can not get to the end of the tube;

- The tube is not rigid enough (too low static pressure) becomes limp and can block the passage of air, especially where there are obstacles.

| Order-driven inventory | |

| Diameter (inflated) | 18 " |